ALUMINIUM PROFILES

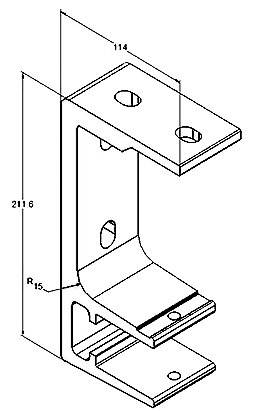

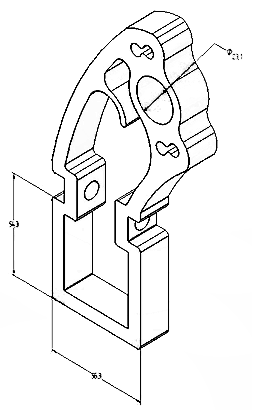

Our aluminum profile production service is based on the aluminum extrusion process. It is usually applied both to the process and to the product obtained when a hot cylindrical aluminum ingot, that is, the billet, passes through a die with the appropriate shape (direct or forward extrusion). The resulting aluminum profile can be used in long lengths, or can be cut for use in structures or as part of a system component in multiple applications and sectors. Likewise, extruded aluminum profiles are also used as raw material for machined profiles.