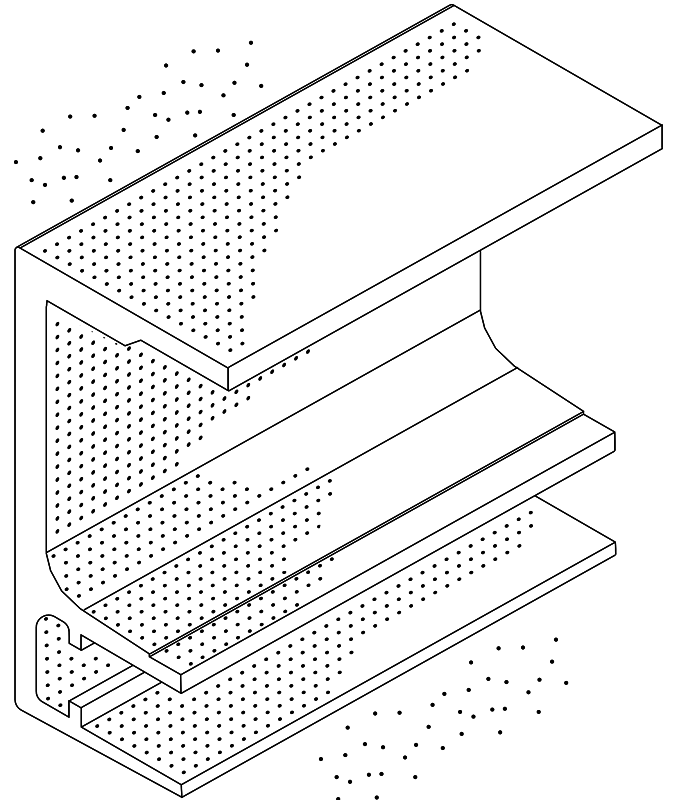

ALUMINIUM PROFILES LACQUERING

We have a vertical lacquering line for aluminium profiles that allows us to lacquer profiles up to 7,5 meters length and an annual capacity of 2.000.000 square meters.

The key to obtain good durability, conservation and lacquered finish lies in carrying out an optimal chemical pre-treatment of the aluminium surface, the use of quality products, especially paint, and finally a correct application and control of the paint in cabin.

The key to obtain good durability, conservation and lacquered finish lies in carrying out an optimal chemical pre-treatment of the aluminium surface, the use of quality products, especially paint, and finally a correct application and control of the paint in cabin.